California Waterjet Cutting Services

Dix Metals offers precision waterjet cutting services in California with state-of-the-art CAD-equipped units. The speed and accuracy of this cutting technique gives you both cost efficiency and precision, allowing faster production and profitability. Our facility is based in Huntington Beach, California, and we offer our waterjet cutting services for U.S. and global customers.

Our top-of-the-line equipment from Flow International® allows us to cut virtually any materials, including stainless steel, cast iron bronze, copper, and aluminum plate. Flow's exclusive HyperPressure waterjet velocity also cuts other materials effortlessly.

Waterjet Cutting Advantages

Our precision waterjet cutting services offer customers numerous advantages:

- Speed: Abrasive waterjet cutting is up to four times faster than conventional flat stock waterjet cutting.

- Precision: Our machines meet the strictest tolerances, up to +/- 0.005".

- Versatility: We cut a wide variety of materials with near net accuracy, virtually eliminating secondary finish machining.

- High material usage: Waterjet cutting maximizes material usage through tight nesting, which lowers your cost per part. Taper is all but eliminated, with less than 1 degree in straight-line geometry.

- No heat-affected zones: Waterjet cutting eliminates heat-affected zones and offers true part-stacking ability, with consistent tolerance layer to layer. This ensures that there is no burning or melting on cut materials.

- Excellent edge quality: The superior accuracy that results from importing any CAD file directly into a FlowMaster® waterjet creates an excellent edge quality. This makes it possible to cut complex shapes efficiently.

- Finish cut: Waterjet cutting is considered a "finish cut," immediately usable for signs and displays, which saves on finishing costs.

- Quality: High quality of cuts on waterjet cutting machines than most other competitors in the industry.

- Cost-effectiveness: Cost savings per part are unmatched by any other cutting system.

- Sustainability: Due to its precision, waterjet cutting generates little waste. Additionally, Dix Metals collects and recycles all scrap material, including the garnet used as the abrasive in the cutting process.

Learn more about the advantages of precision waterjet cutting services on our FAQ.

Waterjet Cutting Materials

Dix Metals offers precision waterjet cutting on any of the following materials (see examples in our project portfolio):

- Aluminum

- Stainless Steel

- Bronze

- Steel

- Raw metal

- Composite

- Tool steels

- Cast iron

- Mold plate

- Copper

- Stone

- Glass

- Ferrous or non-ferrous metals

Waterjet Cutting Industries

Dix Metals provides abrasive waterjet cutting to a large range of industries that demand highly accurate, cost-effective, machine-ready blanks.

- Machine shop OEMs

- Automotive and automotive aftermarket suppliers

- General contractors and architects

- Aerospace manufacturers

- Military organizations

- Race car component builders

- Medical device makers

- Sign manufacturers

- Commercial packaging and display manufacturers

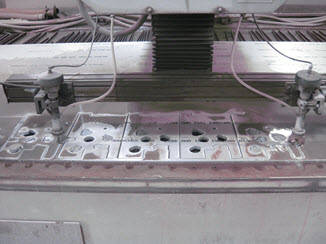

Flow Waterjet Cutting Equipment

Dix Metals employs two Flow International abrasive waterjets. The active tolerance control on these cutters gives us the capability to cut parts up to four times faster than conventional waterjet cutting machines. Our senior-level waterjet machine operators are highly trained to handle the most challenging projects.

- Our Flow Cut Dynamic head machine, delivering over 60,000 PSI, provides incredible cutting tolerances from virtually any CAD file.

- Our Flow Cut Dual head machine cuts with 60,0000 PSI, providing cuts with a superior edge quality that reduces part costs and saves time.

To learn more about Dix Metals and the benefits of our precision waterjet cutting services for your business, please contact us today.

Click here to Request a Quote or call us at 800-477-4349